Sodium-Ion vs. Lithium-Ion Batteries

Sodium-Ion vs. Lithium-Ion Batteries - A Clear Winner?

Introduction

In today’s energy-hungry world, the demand for efficient and reliable energy storage solutions has never been higher. Two technologies currently at the forefront of this industry are Sodium-Ion and Lithium-Ion batteries. Both offer unique advantages, and their differences can impact everything from safety and performance to environmental impact. As we explore these technologies, this blog aims to provide a balanced, technical yet accessible comparison to help readers understand the strengths and limitations of both Sodium-Ion and Lithium-Ion batteries.

Understanding the Basics

What is Sodium-Ion Technology?

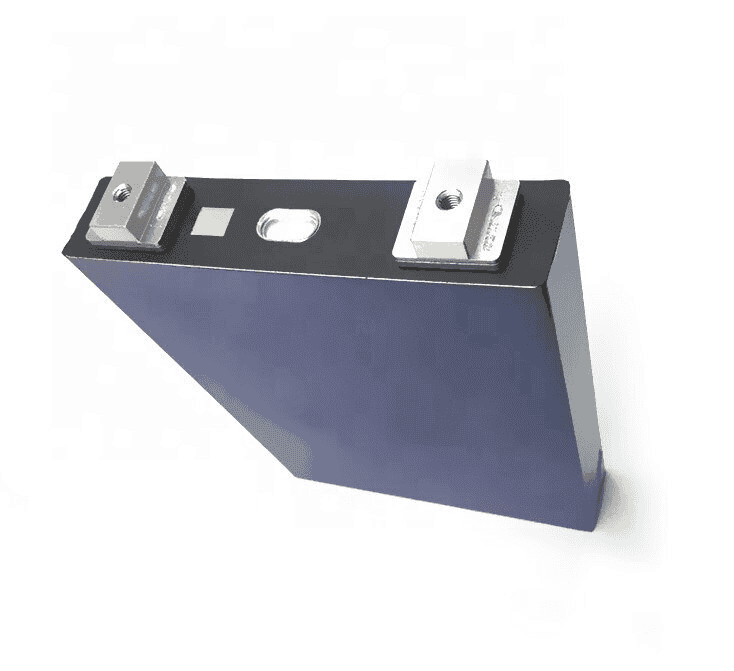

Sodium-Ion battery technology is a relatively new contender in the field of energy storage. It operates on a similar principle to Lithium-Ion batteries, where ions move between the anode and cathode during charge and discharge cycles. However, instead of relying on lithium, Sodium-Ion batteries use sodium ions. Sodium, being one of the most abundant elements on Earth, offers a more sustainable and, in time is expected to be a more cost-effective alternative once the technology becomes more mainstream. The core chemistry involves a sodium-based compound in the cathode and a sodium salt solution as the electrolyte, which facilitates ion movement.

Historically, the development of Sodium-Ion batteries lagged behind Lithium-Ion because of lower energy densities and challenges with performance in early prototypes. However, recent advancements in materials science have significantly improved their efficiency, making Sodium-Ion batteries increasingly viable for practical applications. Current usage primarily focuses on industries requiring high safety and wide operating temperature ranges, such as renewable energy systems, backup power for remote locations, and emerging markets like electric vehicles. Manufacturers like Exotronic have capitalised on these improvements, positioning Sodium-Ion as a competitive alternative in specialised fields.

What is Lithium-Ion Technology?

Lithium-Ion batteries have long been the dominant force in energy storage. Their core chemistry relies on lithium ions moving between a carbon-based anode and a lithium compound cathode. The lightweight nature of lithium and its high electrochemical potential give Lithium-Ion batteries a significant energy density advantage, which has driven their widespread adoption across various industries. Whether in consumer electronics, electric vehicles, or grid storage, Lithium-Ion has become synonymous with modern battery technology.

Lithium-Ion batteries have long been the dominant force in energy storage. Their core chemistry relies on lithium ions moving between a carbon-based anode and a lithium compound cathode. The lightweight nature of lithium and its high electrochemical potential give Lithium-Ion batteries a significant energy density advantage, which has driven their widespread adoption across various industries. Whether in consumer electronics, electric vehicles, or grid storage, Lithium-Ion has become synonymous with modern battery technology.

Since their commercialisation in the early 1990s, Lithium-Ion batteries have continued to evolve, benefiting from ongoing research and development. Their compact size, high energy capacity, and long cycle life make them ideal for portable devices like smartphones and laptops, as well as large-scale applications such as electric vehicle batteries and grid-level storage. Despite their widespread use, challenges remain, particularly in safety and environmental sustainability, which have driven interest in alternative technologies like Sodium-Ion.

Comparing Performance: Energy Density and Efficiency

Energy Density in Sodium-Ion vs. Lithium-Ion

Energy density, which refers to the amount of energy a battery can store relative to its size and weight, plays a crucial role in determining a battery’s performance. Lithium-Ion batteries are well known for their high energy density, often ranging between 150-250 Wh/kg, making them ideal for applications where space and weight are critical factors, such as in electric vehicles or portable electronics. The lightweight properties of lithium, combined with its high electrochemical potential, allow these batteries to pack more power into smaller, lighter units.

On the other hand, Sodium-Ion batteries typically have lower energy densities, usually around 90-150 Wh/kg. This is primarily due to the larger size and heavier mass of sodium ions compared to lithium ions, which limits how much energy can be stored in a given volume. While this makes Sodium-Ion batteries less suited for space-constrained applications, it doesn't diminish their value in areas where size and weight are less critical, such as grid storage or backup power systems. Although the energy density is lower, recent advancements have helped bridge the gap, making Sodium-Ion a more viable alternative for certain use cases.

Pros and Cons for Each Battery Type

When considering the pros and cons of energy capacity, Lithium-Ion clearly excels in delivering higher energy outp ut per unit of weight, making it the preferred choice in industries like consumer electronics and electric vehicles. However, this advantage comes with certain drawbacks, particularly in cost and safety. Lithium-Ion batteries are more expensive to produce, as lithium is less abundant and mining it has significant environmental implications. Additionally, the high energy density in lithium-based batteries increases the risk of overheating or thermal runaway, a serious safety concern.

ut per unit of weight, making it the preferred choice in industries like consumer electronics and electric vehicles. However, this advantage comes with certain drawbacks, particularly in cost and safety. Lithium-Ion batteries are more expensive to produce, as lithium is less abundant and mining it has significant environmental implications. Additionally, the high energy density in lithium-based batteries increases the risk of overheating or thermal runaway, a serious safety concern.

In contrast, Sodium-Ion batteries offer a more affordable and environmentally friendly alternative, though with lower energy capacity. The use of abundant sodium significantly reduces material costs, and the lower energy density actually enhances safety by reducing the likelihood of overheating. Sodium-Ion technology is a practical choice in applications where energy capacity can be slightly compromised for the sake of safety, cost, or environmental sustainability, such as renewable energy storage or stationary power systems.

Efficiency in Real-World Applications

Efficiency in real-world applications is another critical factor when comparing Sodium-Ion and Lithium-Ion batteries. Lithium-Ion batteries are known for their high efficiency, typically around 90-95%, meaning most of the stored energy can be utilised during discharge. This high efficiency makes them an excellent choice for applications that demand quick charging, long runtimes, and high power output, such as electric vehicles, laptops, and smartphones. However, their efficiency drops in extreme temperature conditions, with performance degrading in both very high and low temperatures.

Sodium-Ion batteries, while slightly less efficient in terms of energy density, excel in environments where temperature extremes are common. With a wider operating temperature range, they can continue functioning effectively even in sub-zero conditions, which makes them ideal for outdoor and remote applications like renewable energy storage or RVs. This thermal tolerance, coupled with their ability to withstand deep discharges without performance degradation, gives Sodium-Ion an edge in durability and reliability in harsh environments, where Lithium-Ion batteries might falter.

Performance in Different Environments

In mobile applications like electric vehicles, Lithium-Ion batteries remain the go-to choice due to their superior energy density, which translates into longer driving ranges and faster charging times. However, their sensitivity to extreme temperatures and potential safety risks make them less reliable in certain outdoor or industrial settings. For instance, in environments with extreme cold or heat, Lithium-Ion batteries may require additional thermal management systems, which can increase costs and complexity.

Sodium-Ion batteries, with their robust performance in harsh environments, offer a viable alternative for outdoor and industrial applications. Their ability to operate efficiently in sub-zero temperatures without the need for complex thermal management systems gives them a distinct advantage in settings like renewable energy storage, caravans, or off-grid power systems. Although Sodium-Ion batteries may not deliver the same high energy density as their lithium counterparts, their stability, safety, and environmental resilience make them the preferred option for specific niche markets where reliability in challenging conditions outweighs the need for maximum energy capacity.

Temperature Tolerance and Durability

Operating Temperature Ranges

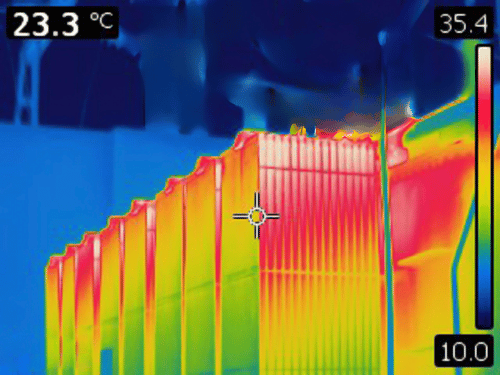

One of the key strengths of Sodium-Ion batteries is their ability to operate across a wide range of temperatures, m.png) aking them highly versatile in environments where other battery technologies might struggle. The Exotronic Guardian, for instance, showcases this capability by reliably functioning in sub-zero temperatures without significant performance loss. This wider operating temperature range, typically from -20°C to 60°C, allows Sodium-Ion batteries to excel in outdoor, mobile, and off-grid applications, such as in RVs, remote locations, or backup power systems for harsh climates. This resilience to cold makes them particularly suitable for regions with extreme weather, where energy storage must remain reliable despite fluctuating temperatures.

aking them highly versatile in environments where other battery technologies might struggle. The Exotronic Guardian, for instance, showcases this capability by reliably functioning in sub-zero temperatures without significant performance loss. This wider operating temperature range, typically from -20°C to 60°C, allows Sodium-Ion batteries to excel in outdoor, mobile, and off-grid applications, such as in RVs, remote locations, or backup power systems for harsh climates. This resilience to cold makes them particularly suitable for regions with extreme weather, where energy storage must remain reliable despite fluctuating temperatures.

In contrast, Lithium-Ion batteries have more limited temperature tolerances. While they perform optimally in moderate climates, they tend to lose efficiency and experience shortened lifespans in extreme heat or cold. In colder environments, for instance, Lithium-Ion batteries may require heating elements or other external thermal management systems to prevent degradation, and they can become less reliable if not managed properly. In hotter climates, the risk of overheating can lead to safety concerns, including the possibility of thermal runaway. These temperature sensitivities make Lithium-Ion batteries less suitable for certain outdoor or mission-critical applications without additional engineering solutions.

Durability Over Time

Durability is another area where Sodium-Ion and Lithium-Ion batteries diverge. Sodium-Ion batteries are known for their robust ability to withstand frequent.png) and deep discharges without suffering from significant degradation. This makes them well-suited for applications that require regular cycling, such as renewable energy storage systems where batteries are constantly charged and discharged based on solar or wind availability. The Exotronic Guardian, for example, can endure frequent deep discharges without compromising its long-term performance, allowing users to drain the battery to low levels and still maintain reliability over time. This characteristic extends the overall lifespan of Sodium-Ion batteries, providing a solid return on investment in applications where long-term durability is crucial.

and deep discharges without suffering from significant degradation. This makes them well-suited for applications that require regular cycling, such as renewable energy storage systems where batteries are constantly charged and discharged based on solar or wind availability. The Exotronic Guardian, for example, can endure frequent deep discharges without compromising its long-term performance, allowing users to drain the battery to low levels and still maintain reliability over time. This characteristic extends the overall lifespan of Sodium-Ion batteries, providing a solid return on investment in applications where long-term durability is crucial.

Lithium-Ion batteries, while highly efficient, are more sensitive to deep discharges and frequent cycling. Over time, repeated deep discharges can reduce their capacity, shorten their lifespan, and require more maintenance. While modern Battery Management Systems (BMS) mitigate some of these risks by preventing excessive discharge or overcharging, Lithium-Ion batteries generally require more careful handling to maximise their longevity. In high-demand applications like electric vehicles or portable electronics, where frequent charging cycles are the norm, this reduced tolerance to frequent deep discharges can necessitate more frequent battery replacements compared to their Sodium-Ion counterparts.

Handling Frequent Discharges

In practical terms, the difference in handling frequent discharges comes down to how each technology manages stress over time. Sodium-Ion batteries can tolerate deep discharges without much impact on performance, making them ideal for off-grid systems where energy might not be consistently available, or where cycling through the battery’s full capacity is necessary. Their ability to handle these stresses without a steep decline in capacity over time means fewer worries about managing state of charge or depth of discharge, leading to longer service life and lower maintenance.

Lithium-Ion batteries, despite their high initial efficiency, require more careful management to prevent damage from frequent deep discharges. Although they typically have a higher energy density, this advantage is offset by the fact that improper cycling can lead to faster capacity loss. Battery degradation in Lithium-Ion systems is often tied to the frequency and depth of discharge cycles, which makes them more suitable for applications with stable charging patterns, such as in consumer electronics or electric vehicles that follow controlled charging regimens.

Long-Term Durability

When it comes to long-term durability, both Sodium-Ion and Lithium-Ion batteries can provide extended service life, but under different conditions. Sodium-Ion batteries generally exhibit better durability in environments where frequent, deep discharges are required, along with challenging temperature conditions. Their robust nature and tolerance to environmental stresses make them an excellent choice for grid storage, renewable energy systems, or remote installations where access for maintenance or replacement may be limited. Their ability to maintain consistent performance despite these stresses contributes to their reputation as a durable, low-maintenance option.

Lithium-Ion batteries, on the other hand, excel in applications where efficiency and energy density are prioritised but require more controlled conditions for long-term durability. With appropriate management, including moderate cycling and temperature control, Lithium-Ion batteries can offer years of reliable service. However, without these protections, they may degrade more quickly, especially in environments with frequent deep discharges or extreme temperatures. This makes them more suited to applications like consumer electronics or electric vehicles, where these conditions can be closely monitored and managed.

Safety: A Critical Factor

Sodium-Ion Safety Advantages

Sodium-Ion batteries are renowned for their inherent safety, largely due to the absence of thermal runaway risk. Thermal runaway is  a dangerous condition where a battery overheats uncontrollably, potentially leading to fires or explosions. Sodium-Ion chemistry is fundamentally more stable, making it highly resistant to this phenomenon. This stability, even under stressful conditions such as overcharging, short circuits, or physical damage, makes Sodium-Ion batteries a preferred choice in environments where safety is a top priority, such as off-grid systems, industrial applications, and harsh environments like RVs and caravans. The Exotronic Guardian series, for instance, offers excellent safety features, providing users with a reliable and worry-free energy solution.

a dangerous condition where a battery overheats uncontrollably, potentially leading to fires or explosions. Sodium-Ion chemistry is fundamentally more stable, making it highly resistant to this phenomenon. This stability, even under stressful conditions such as overcharging, short circuits, or physical damage, makes Sodium-Ion batteries a preferred choice in environments where safety is a top priority, such as off-grid systems, industrial applications, and harsh environments like RVs and caravans. The Exotronic Guardian series, for instance, offers excellent safety features, providing users with a reliable and worry-free energy solution.

Another important safety consideration is that Sodium-Ion batteries are not currently classified as dangerous goods, which simplifies their transportation and handling compared to certain lithium-ion chemistries. This is a significant advantage for industries where logistics and safety regulations are stringent. However, it’s important to note that any short-circuited battery, including Sodium-Ion, can still pose safety risks due to the potential for arcing and heat generation, which can cause damage if not properly managed. Despite this, the overall risk of catastrophic failure in Sodium-Ion batteries is much lower than in other chemistries, making them inherently safer in most applications.

In addition to the low risk of thermal runaway, Sodium-Ion batteries do not require complex cooling or safety management systems, making them simpler and more affordable to implement in large-scale applications. Their wide operating temperature range and stable chemistry contribute to their overall safety, making them a robust option for users who need reliable energy storage in both everyday and extreme conditions.

LiFePO4 Lithium-Ion: A Safer Lithium Chemistry

While Lithium-Ion batteries, particularly in chemistries like lithium-polymer (LiPo) and nickel-cobalt-manganese (NCM), are often associated with safety concerns due to the risk of thermal runaway, Lithium Iron Phosphate (LiFePO4) stands out as a much safer alternative within the lithium-ion family. LiFePO4 batteries are known for their exceptional thermal stability and resistance to overheating, which significantly reduces the likelihood of thermal runaway. This makes LiFePO4 batteries far safer than other lithium chemistries, even under stressful conditions such as high temperatures or deep discharges.

While thermal runaway is technically possible with LiFePO4, it is extremely rare compared to other lithium-ion chemistries like LiPo and NCM. LiFePO4’s strong chemical bonds and stable structure help prevent dangerous reactions, even when the battery is damaged or improperly charged. This has made LiFePO4 popular in applications where safety is crucial, such as in electric vehicles, stationary power storage, and renewable energy systems. The combination of high energy density, long cycle life, and enhanced safety makes LiFePO4 a compelling choice for many applications.

Comparing Sodium-Ion and LiFePO4 in Terms of Safety

Both Sodium-Ion and LiFePO4 batteries offer excellent safety profiles, but they achieve this in different ways. Sodium-Ion batteries eliminate the risk of thermal runaway altogether due to their inherently stable chemistry, while LiFePO4 significantly reduces the risk, making it highly unlikely but not impossible. This makes Sodium-Ion slightly safer in absolute terms, especially in applications where even a small risk of thermal runaway is unacceptable. However, LiFePO4’s risk is already so low that it is considered one of the safest lithium chemistries on the market.

Both Sodium-Ion and LiFePO4 batteries offer excellent safety profiles, but they achieve this in different ways. Sodium-Ion batteries eliminate the risk of thermal runaway altogether due to their inherently stable chemistry, while LiFePO4 significantly reduces the risk, making it highly unlikely but not impossible. This makes Sodium-Ion slightly safer in absolute terms, especially in applications where even a small risk of thermal runaway is unacceptable. However, LiFePO4’s risk is already so low that it is considered one of the safest lithium chemistries on the market.

One key difference between the two technologies is their need for additional safety systems. LiFePO4 batteries often require Battery Management Systems (BMS) to monitor and manage charge cycles, temperature, and overall health, ensuring the battery operates within safe parameters. Although the likelihood of thermal runaway is very low, the BMS acts as a safeguard. Sodium-Ion batteries, on the other hand, require less complex safety management due to their lower inherent risk, which simplifies their use in large-scale or mission-critical applications.

Overall Safety Considerations

For users focused on maximising safety, both Sodium-Ion and LiFePO4 present strong options. Sodium-Ion, with its complete elimination of thermal runaway risk, offers an edge in scenarios where safety is paramount, particularly in harsh environments where batteries might face extreme conditions. LiFePO4, while not entirely free from the risk of thermal runaway, offers a highly stable alternative within the lithium-ion family, making it suitable for most applications where high energy density and long cycle life are required without compromising safety. Both technologies allow users to operate with confidence, but the final choice often depends on the specific needs of the application, including energy density requirements, cost considerations, and environmental conditions.

Environmental Impact

Sodium-Ion: A Greener Alternative

One of the key advantages of Sodium-Ion technology is its potential to offer a more sustainable alternative to traditional Lithium-Ion batteries. Sodium, the primary element used in Sodium-Ion batteries, is one of the most abundant elements on Earth. Unlike lithium, sodium is readily available, inexpensive to mine, and widely distributed across various regions. This abundance drastically reduces the environmental impact associated with resource extraction and transportation, making Sodium-Ion batteries a greener option from the very start of their production cycle.

The lower environmental cost of sodium extraction translates into a more sustainable supply chain. Sodium mining does not require the same level of environmental disruption as lithium mining, which often involves intensive water usage and can lead to ecological damage in sensitive areas like salt flats and arid regions. In this sense, Sodium-Ion batteries can play a significant role in contributing to a sustainable future, especially as the demand for renewable energy storage continues to grow. By shifting to materials that are abundant and less damaging to extract, Sodium-Ion technology helps reduce the ecological footprint of energy storage systems, making them more environmentally friendly over their lifecycle.

Lithium-Ion: Concerns and Mitigations

While Lithium-Ion batteries have revolutionised energy storage across numerous industries, their environmen tal impact is a growing concern. Lithium is primarily sourced from regions with fragile ecosystems, such as the salt flats of South America, where extraction processes involve the use of large quantities of water. In some cases, the water-intensive nature of lithium extraction has led to water scarcity issues, impacting local communities and ecosystems. Additionally, cobalt, another critical element in many lithium-ion chemistries, is often sourced from mines with questionable labor practices and environmental standards, further contributing to the negative environmental impact of Lithium-Ion battery production.

tal impact is a growing concern. Lithium is primarily sourced from regions with fragile ecosystems, such as the salt flats of South America, where extraction processes involve the use of large quantities of water. In some cases, the water-intensive nature of lithium extraction has led to water scarcity issues, impacting local communities and ecosystems. Additionally, cobalt, another critical element in many lithium-ion chemistries, is often sourced from mines with questionable labor practices and environmental standards, further contributing to the negative environmental impact of Lithium-Ion battery production.

To mitigate these environmental concerns, the industry has been exploring several initiatives. One significant focus is on improving recycling processes for Lithium-Ion batteries, which would reduce the need for raw material extraction. However, recycling Lithium-Ion batteries presents challenges due to the complexity of the materials involved and the cost of the recycling process itself. While there have been advances in battery recycling technology, only a fraction of lithium batteries are currently recycled, leaving much room for improvement. Additionally, some manufacturers are exploring alternative chemistries, such as Lithium-Iron Phosphate (LiFePO4), which use fewer toxic materials and are easier to recycle than traditional Lithium-Ion batteries containing cobalt.

How Sodium-Ion Can Contribute to a Sustainable Future

Sodium-Ion batteries offer a significant advantage in terms of sustainability because they rely on a more eco-friendly and readily available resource. Sodium is not only abundant but also less resource-intensive to extract and process. The environmental costs of mining sodium are considerably lower compared to lithium, reducing the overall carbon footprint of battery production. This positions Sodium-Ion technology as a key player in the push toward more sustainable energy solutions, particularly for large-scale applications like grid storage, where environmental considerations are critical.

By shifting the focus away from materials like lithium and cobalt, Sodium-Ion batteries reduce the reliance on environmentally damaging mining operations. Additionally, sodium extraction has fewer associated social and ecological risks, making it a more ethically sustainable option for battery manufacturers. As the world transitions to renewable energy sources, the environmental impact of energy storage technologies will play an increasingly important role. Sodium-Ion batteries, with their greener profile, can help meet global energy needs while minimising harm to the planet.

Lithium-Ion Recycling Initiatives and Their Challenges

Lithium-Ion Recycling Initiatives and Their Challenges

Despite its environmental challenges, the Lithium-Ion battery industry has made strides in developing recycling initiatives to reduce its ecological impact. Recycling Lithium-Ion batteries can recover valuable materials like lithium, cobalt, and nickel, which can then be reused in new batteries. However, the recycling process is costly, complex, and not yet fully optimised. Current recycling efforts are limited in scale, and only a small percentage of the millions of Lithium-Ion batteries produced annually are successfully recycled.

The challenge lies in the diversity of Lithium-Ion chemistries, which complicates the recycling process. Additionally, the collection and transport of used batteries pose logistical hurdles, particularly for small consumer devices like smartphones and laptops. While advancements in recycling technology are expected to improve over time, it will take significant industry investment and regulatory support to make large-scale lithium recycling viable. Until then, the environmental impact of Lithium-Ion batteries will remain a concern, highlighting the need for alternatives like Sodium-Ion, which offer both sustainability and performance benefits

Key Insights

-

Lithium-Ion's Place in Premium Applications:

- Lithium-Ion remains the top choice for high-performance marine and RV applications, offering the best energy density for maximising power in compact spaces. Ideal for long-haul trips requiring lightweight, high-efficiency batteries.

-

Lithium-Ion Safety Concerns in Extreme Applications:

- The risk of overheating is more significant in high-demand sectors like aviation and large-scale storage.

- Increasing regulatory scrutiny on lithium mining due to its environmental and social impact may affect future supply and costs.

-

Potential for Sodium-Ion in Emerging Markets:

- Sodium-Ion's enhanced safety profile make it a promising contender in renewable energy, large-scale grid and residential storage applications.

- Its ability to perform in diverse climates positions it well for developing regions with harsh environmental conditions.

-

Energy Storage in Remote and Off-Grid Systems:

- Sodium-Ion batteries are durable and handle deep discharges, making them a sustainable choice for off-grid and remote installations, such as rural electrification and disaster relief.

Battery Management and Usability

State of Charge Estimation

One of the clear advantages of Sodium-Ion batteries is the ease and precision of state of charge (SoC) estimation, thanks to their linear voltage-to-charge relationship. In a Sodium-Ion battery, the voltage increases in a predictable, linear fashion as the battery charges, which makes it simpler to gauge the battery’s exact state of charge at any given time. This straightforward relationship reduces the need for complex algorithms or advanced battery management systems (BMS) to estimate the remaining capacity, resulting in more accurate and reliable power management for users. For applications where precise control over battery usage is critical—such as in renewable energy systems or off-grid applications—this characteristic gives Sodium-Ion batteries an operational edge.

In contrast, Lithium-Ion batteries, while powerful and efficient, exhibit a more complex voltage-to-charge relationship. The voltage curve of a Lithium-Ion battery is nonlinear, especially in the mid-range of the battery’s charge. As a result, accurately determining the state of charge often requires advanced BMS technology and software algorithms to interpret voltage, current, and temperature data. These systems calculate an estimate, but the margin of error is greater compared to Sodium-Ion batteries. For applications that demand fine-grained control over battery charge levels—such as electric vehicles or backup power systems—this complexity can make energy management more challenging.

Charging and Discharging Characteristics

When it comes to charging and discharging characteristics, Sodium-Ion and Lithium-Ion batteries behave quite differently, impacting how they perform in real-world applications. One of the distinct advantages of Sodium-Ion batteries is their gradual power down as they discharge. In systems like the Exotronic Guardian series, Sodium-Ion batteries can discharge down to lower voltages (around 6V) before their Battery Management System (BMS) cuts off power. This allows connected devices to gradually wind down instead of experiencing an abrupt loss of power, which is particularly useful in mission-critical applications where a sudden shutdown could result in data loss or equipment failure.

On the other hand, Lithium-Ion batteries are known for their sudden power cut-off when they reach a critical low voltage, typically to protect the battery from deep discharge damage. This characteristic can lead to unexpected shutdowns, especially in systems that are not equipped with sufficient backup measures. For example, in devices like laptops or electric vehicles, a sudden loss of power due to a rapid discharge can be inconvenient or even hazardous. While modern BMS systems have mitigated some of these effects by providing early warnings or buffering power, the sudden cut-off behavior remains a limitation in Lithium-Ion technology.

Usable Capacity Limitations in Standard Setups

Another aspect of battery management is the usable capacity of each battery type in standard setups. In Sodium-Ion batteries, the usable capacity is often limited by the voltage range that devices can accommodate. For example, while the Exotronic Guardian can operate between 6V and 15.9V, many standard 12V systems will shut down when the voltage drops to around 10V. This effectively limits the amount of usable capacity available to the user unless their devices can handle the full voltage range. Although this limitation might seem like a drawback, it is more a result of system compatibility rather than the inherent performance of the Sodium-Ion battery itself.

Lithium-Ion batteries face a similar issue, albeit in a different way. Usable capacity is typically restricted by the need to protect the battery from over-discharge and overcharge. Lithium-Ion batteries generally operate within a tighter voltage range to avoid damage to the battery cells. This means that although the theoretical capacity of the battery may be higher, the practical usable capacity is often lower, as BMS systems cut off power to avoid deep discharges that would shorten the battery’s lifespan. While Lithium-Ion batteries offer higher energy density, the limitations imposed by these protective measures reduce the amount of energy that can be safely utilised in many applications.

Battery Management in Real-World Use

In real-world scenarios, both Sodium-Ion and Lithium-Ion batteries benefit from battery management systems to optimise their performance and ensure safety. However, the simplicity of Sodium-Ion’s state of charge estimation and gradual discharge behavior allows for a more straightforward and user-friendly experience. Applications that require smooth transitions during power-down, such as medical devices or industrial control systems, can particularly benefit from Sodium-Ion’s management characteristics. Conversely, Lithium-Ion batteries, while offering higher energy density, require more complex management and can be more unpredictable during discharge, especially in high-stress applications like electric vehicles, where the sudden power cut-off may necessitate more advanced contingency planning.

In summary, while both technologies offer robust solutions for different use cases, Sodium-Ion batteries provide a more user-friendly experience with fewer management complexities, especially in terms of SoC estimation and discharge behavior. Lithium-Ion, with its higher energy density, remains ideal for portable applications but requires more sophisticated management to maximise efficiency and safety.

Cost and Availability

Current Market Availability

Sodium-Ion battery technology, while gaining momentum, remai ns in the early stages of market adoption. As an emerging alternative to Lithium-Ion, Sodium-Ion batteries are gradually becoming more available, especially in niche applications like renewable energy storage, off-grid systems, and specialised industries. Companies like Exotronic have begun introducing Sodium-Ion products, but the technology has not yet reached the widespread commercial penetration of Lithium-Ion batteries. As the demand for more sustainable and safer energy storage solutions grows, the availability of Sodium-Ion batteries is expected to expand, with ongoing research and production improvements driving this shift.

ns in the early stages of market adoption. As an emerging alternative to Lithium-Ion, Sodium-Ion batteries are gradually becoming more available, especially in niche applications like renewable energy storage, off-grid systems, and specialised industries. Companies like Exotronic have begun introducing Sodium-Ion products, but the technology has not yet reached the widespread commercial penetration of Lithium-Ion batteries. As the demand for more sustainable and safer energy storage solutions grows, the availability of Sodium-Ion batteries is expected to expand, with ongoing research and production improvements driving this shift.

In contrast, Lithium-Ion batteries have long dominated the energy storage market. Their widespread use in consumer electronics, electric vehicles, and large-scale energy storage systems has established them as the industry standard. The mature supply chain and well-developed manufacturing infrastructure mean that Lithium-Ion batteries are widely available across the globe. The extensive market presence of Lithium-Ion allows consumers and businesses easy access to a range of products in various sizes, configurations, and capacities. This established presence has led to significant economies of scale, making Lithium-Ion batteries both accessible and relatively affordable compared to newer technologies.

Cost Considerations

From a cost perspective, Sodium-Ion batteries present both challenges and opportunities. As an emerging technology, initial production costs for Sodium-Ion batteries are higher due to smaller-scale manufacturing and less mature supply chains. However, Sodium-Ion offers a significant advantage in terms of raw material costs, as sodium is far more abundant and cheaper to extract than lithium. As manufacturing scales up and processes become more efficient, Sodium-Ion batteries are expected to become a more cost-competitive alternative. Additionally, the longer lifespan and lower maintenance requirements of Sodium-Ion batteries contribute to better long-term value, particularly in applications where safety and durability are prioritised over energy density.

From a cost perspective, Sodium-Ion batteries present both challenges and opportunities. As an emerging technology, initial production costs for Sodium-Ion batteries are higher due to smaller-scale manufacturing and less mature supply chains. However, Sodium-Ion offers a significant advantage in terms of raw material costs, as sodium is far more abundant and cheaper to extract than lithium. As manufacturing scales up and processes become more efficient, Sodium-Ion batteries are expected to become a more cost-competitive alternative. Additionally, the longer lifespan and lower maintenance requirements of Sodium-Ion batteries contribute to better long-term value, particularly in applications where safety and durability are prioritised over energy density.

Lithium-Ion batteries, on the other hand, benefit from well-established production lines, which have driven down the costs over time. The initial cost of a Lithium-Ion battery is generally lower than that of a Sodium-Ion battery, especially for high-demand products like those used in electric vehicles or consumer electronics. However, Lithium-Ion batteries come with certain hidden costs, including the need for more advanced Battery Management Systems (BMS) and potentially higher maintenance, especially in high-stress applications where overheating or deep discharges could shorten battery life. Over the long term, Lithium-Ion batteries may require more frequent replacements, which can increase the total cost of ownership.

Comparison of Initial Costs and Long-Term Value

When comparing initial costs, Lithium-Ion batteries have the clear advantage, benefiting from mass production and economies of scale. For consumers and businesses looking for readily available, affordable energy storage, Lithium-Ion batteries are often the first choice. However, this lower upfront cost can be offset by the need for additional safety measures, replacement cycles, and environmental concerns related to material extraction and disposal.

Sodium-Ion batteries, though more expensive initially, offer promising long-term value. Their lower environmental impact, coupled with the use of abundant and inexpensive sodium, reduces the need for costly raw materials. Additionally, the robust safety profile and longer cycle life of Sodium-Ion batteries can result in fewer replacements and lower maintenance costs over time, making them an attractive option for applications that require longevity and reliability. As production scales up and costs come down, Sodium-Ion technology is likely to become more economically competitive, particularly for large-scale energy storage and industrial applications where long-term value is a key consideration.

Long Term Cost and Availability

While Sodium-Ion technology is still emerging and has higher initial costs, its long-term value and sustainability advantages make it a strong contender for the future of energy storage. Lithium-Ion, with its well-established market presence and lower upfront costs, remains the dominant choice for most applications today. However, as demand for greener, safer alternatives grows, and as the Sodium-Ion supply chain matures, we can expect a shift in market dynamics, with Sodium-Ion becoming a more prominent player in the energy storage industry

Future Potential

Advancements in Sodium-Ion

Sodium-Ion technology, though still emerging, is rapidly advancing and showing great promise for the future of energy storage. One of the most exciting areas of development is the improvement of energy density. While Sodium-Ion batteries currently lag behind Lithium-Ion in this regard, ongoing research is focused on optimising materials for the cathode and anode to boost their energy storage capabilities. New materials, such as advanced carbon-based anodes and layered oxide cathodes, are showing potential to significantly increase energy density without compromising safety or affordability. This would allow Sodium-Ion batteries to become competitive in a wider range of applications, including electric vehicles and portable electronics, where higher energy density is critical.

energy storage. One of the most exciting areas of development is the improvement of energy density. While Sodium-Ion batteries currently lag behind Lithium-Ion in this regard, ongoing research is focused on optimising materials for the cathode and anode to boost their energy storage capabilities. New materials, such as advanced carbon-based anodes and layered oxide cathodes, are showing potential to significantly increase energy density without compromising safety or affordability. This would allow Sodium-Ion batteries to become competitive in a wider range of applications, including electric vehicles and portable electronics, where higher energy density is critical.

In addition to energy density improvements, Sodium-Ion batteries are benefiting from innovations aimed at enhancing cycle life and overall efficiency. These developments include improvements in electrolyte composition and the use of more efficient separators, which help to reduce degradation over time and extend the battery's lifespan. As production scales up, it is expected that manufacturing costs will decrease, making Sodium-Ion batteries a more affordable and sustainable option for large-scale energy storage, especially in applications like grid storage and renewable energy systems. Furthermore, the focus on sustainability and the use of abundant, non-toxic materials positions Sodium-Ion technology as a key player in the global shift toward greener energy solutions.

Lithium-Ion Developments

Lithium-Ion technology, despite being more mature, continues to see significant advancements. One of the primary areas of focus is extending the cycle life of Lithium-Ion batteries. Manufacturers are developing new cathode materials, such as nickel-rich or cobalt-free chemistries, which not only improve the sustainability of Lithium-Ion batteries but also enhance their durability. These improvements allow Lithium-Ion batteries to last longer and endure more charge-discharge cycles without significant capacity loss, which is particularly important in applications like electric vehicles and renewable energy storage systems, where long-term reliability is crucial.

Another major area of development is the increase in energy density. Researchers are exploring new electrode materials and innovative manufacturing techniques to pack more energy into smaller, lighter battery cells. Solid-state Lithium-Ion batteries are one of the most promising advancements in this space, offering higher energy densities and improved safety by replacing the liquid electrolyte with a solid alternative. This could dramatically increase the range and efficiency of electric vehicles, as well as reduce the size of battery packs in portable devices. Additionally, solid-state batteries are expected to enhance safety by eliminating the flammable liquid electrolyte, further reducing the risk of thermal runaway.

Improvements in Safety Features

While Lithium-Ion batteries have made strides in energy density and cycle life, safety remains a key area of focus. Advanced Battery Management Systems (BMS) are continually being refined to monitor and control the state of charge, temperature, and overall health of Lithium-Ion batteries. These systems are becoming more sophisticated, offering real-time data and predictive analytics that can prevent issues such as overcharging or overheating before they lead to safety concerns. Furthermore, innovations like thermal management coatings and fire-resistant electrolytes are being introduced to mitigate the risks associated with thermal runaway, especially in high-energy applications like electric vehicles.

For Sodium-Ion, safety features are naturally enhanced by the inherent stability of the chemistry, but ongoing developments in BMS technology and cell design will further improve their resilience. As Sodium-Ion technology matures, it is likely that more advanced safety features will be incorporated into the design of these batteries, making them even more attractive for mission-critical applications where safety is paramount.

The Road Ahead

Both Sodium-Ion and Lithium-Ion technologies have bright futures, each evolving to meet the growing demands of energy storage in a world increasingly dependent on renewable energy, electric mobility, and sustainable practices. For Sodium-Ion, the focus on making the technology more commercially viable through advancements in energy density and production efficiency will be key to its wider adoption. For Lithium-Ion, the continual improvements in energy density, cycle life, and safety features will ensure its place in high-performance applications, even as new technologies like solid-state batteries push the boundaries of what is possible.

As these technologies continue to evolve, the choice between Sodium-Ion and Lithium-Ion will depend on the specific needs of the application—whether it be the lower cost and environmental benefits of Sodium-Ion or the high energy density and established infrastructure of Lithium-Ion. Either way, both technologies are set to play crucial roles in the future of energy storage.

Conclusion

When comparing Sodium-Ion and LiFePO4 (Lithium Iron Phosphate) technologies, both offer compelling advantages, but they cater to slightly different needs and applications. Sodium-Ion batteries stand out for their superior safety, affordability, and environmental sustainability. The abundance of sodium as a resource means that Sodium-Ion batteries have a lower environmental cost and do not face the same material constraints as lithium. Additionally, their ability to function in a wide range of temperatures, combined with an inherently stable chemistry that eliminates the risk of thermal runaway, makes them highly reliable in harsh environments. However, Sodium-Ion batteries generally have a lower energy density compared to LiFePO4, which limits their applicability in situations where space and weight are critical considerations.

On the other hand, LiFePO4 batteries, a safer and more stable member of the lithium-ion family, are well-established in the market with a proven track record in RV and marine applications. LiFePO4 batteries offer higher energy density, longer cycle life, and more compact storage, making them ideal for space-constrained environments like RVs and boats. Their excellent thermal stability makes them safer than other lithium chemistries, though not entirely free from risks like thermal runaway. Additionally, LiFePO4’s extensive market presence and advanced battery management systems (BMS) provide an additional layer of reliability and flexibility in mobile and off-grid systems.

Advice for Choosing the Right Battery Technology

For RV and marine applications, where space, weight, and safety are key concerns, LiFePO4 batteries remain the preferred option. Their higher energy density allows for more power storage in smaller spaces, and their long cycle life ensures they can withstand frequent use and recharging in these mobile environments. Furthermore, their durability and safety in moderate temperature ranges make them ideal for mobile energy systems where reliable, high-capacity storage is needed.

However, if safety and cost are your primary considerations—especially in applications where extreme temperatures or less frequent cycling are involved—Sodium-Ion batteries could be an excellent alternative. For those using RVs and boats in rugged, remote environments where temperature fluctuations are common, the ability of Sodium-Ion batteries to operate reliably in sub-zero or very hot conditions without complex thermal management systems is a key advantage. Additionally, their more affordable materials and greener profile make them a sustainable choice for eco-conscious users.

Final Thoughts on the Future of Battery Technologies

As both Sodium-Ion and LiFePO4 technologies continue to evolve, they will complement each other in the future of energy storage solutions. For mobile and marine storage, the focus on safety, durability, and performance will drive the adoption of these technologies. LiFePO4 will likely continue to lead in high-energy, compact applications, while Sodium-Ion will find its niche in areas where cost, safety, and environmental considerations are prioritised.

other in the future of energy storage solutions. For mobile and marine storage, the focus on safety, durability, and performance will drive the adoption of these technologies. LiFePO4 will likely continue to lead in high-energy, compact applications, while Sodium-Ion will find its niche in areas where cost, safety, and environmental considerations are prioritised.

With ongoing advancements in battery chemistry, energy density, and recycling efforts, both Sodium-Ion and LiFePO4 batteries will play critical roles in the transition to sustainable energy solutions. Whether for RVs, marine vessels, or off-grid setups, these technologies offer a reliable, safe, and increasingly environmentally friendly future for energy storage. The key to choosing the right battery lies in understanding your specific needs, balancing factors like space, energy capacity, and cost, and considering the long-term benefits that each technology can offer for your lifestyle and applications.